EMBEDDED THERMAL MONITORING

INSIDE ELECTRICAL PANELS & CABINETS

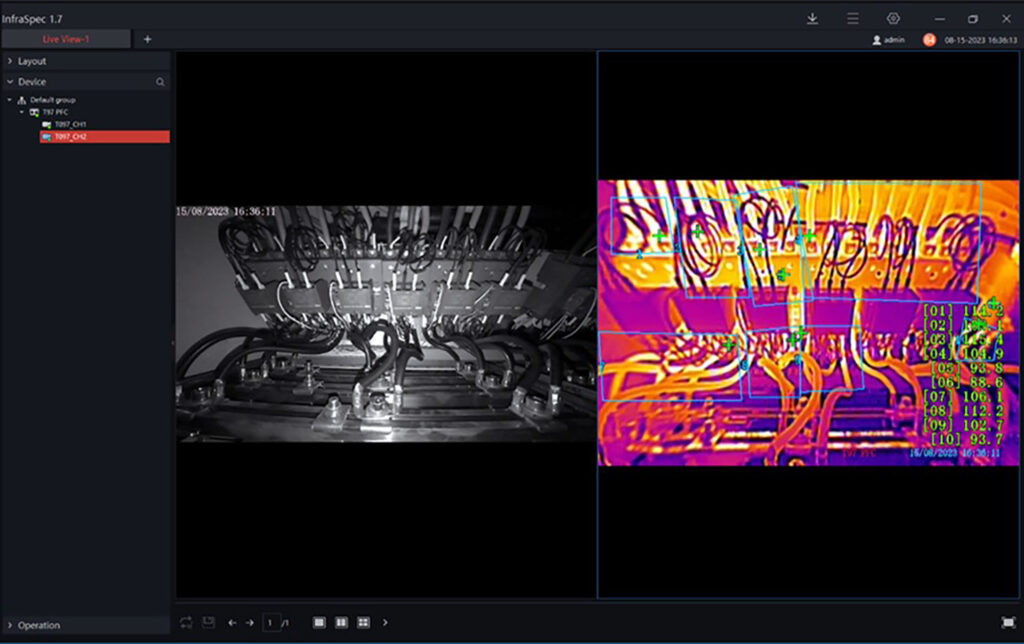

Heat is often the earliest indicator of electrical faults, yet it is rarely monitored continuously inside enclosed equipment. Embedded thermal monitoring provides fixed-position visibility of abnormal heat conditions without requiring routine panel access.

How It

Works

Fixed-position thermal monitoring inside enclosed electrical equipment.

SENSING LOCATION

FIXED POSITION MONITORING

Thermal sensors are installed magnetically in fixed positions inside electrical panels and cabinets, close to components where heat-related faults are most likely to develop.

THERMAL DATA CAPTURE

Continuous thermal measurement

Surface temperature data is continuously measured without physical contact, creating a consistent thermal view of operating conditions over time.

CONTINUOUS AWARENESS

Persistent condition visibility

Ongoing monitoring maintains visibility between site visits by identifying abnormal heat patterns as they emerge rather than relying on periodic inspections.

Why This

Matters

Operational impact of continuous thermal visibility inside electrical equipment.

Reduced personnel

exposure

Monitoring thermal conditions continuously inside energized panels reduces the need for routine manual inspections. This limits technician exposure to arc flash risk and other hazards associated with opening live electrical equipment.

Earlier awareness of developing issues

Electrical faults often begin as gradual thermal changes that are easy to miss during periodic inspections. Continuous monitoring provides earlier awareness of abnormal conditions before visible failure or unplanned outages occur.

Continuous visibility

between inspections

Between scheduled site visits, critical electrical assets are often unobserved. Fixed-position thermal monitoring maintains ongoing visibility, reducing blind spots across distributed infrastructure.

Deployment

Context

Where embedded thermal monitoring is deployed in real-world electrical environments.

Electrical panels and cabinets

Thermal sensors are embedded inside electrical panels and cabinets to provide continuous visibility of internal components without requiring routine access or manual inspection.

Substations and switchgear

Embedded monitoring is deployed within substation equipment and switchgear to track thermal behavior in environments where access is limited and failures can have widespread impact.

Distributed utility assets

Across geographically distributed assets, fixed-position thermal monitoring provides consistent visibility without relying on frequent site visits or handheld inspections.

Industrial control enclosures

Embedded thermal monitoring supports industrial control environments by maintaining awareness of heat-related issues inside enclosed systems operating continuously.

Solution

examples

How embedded thermal monitoring is implemented using SYTIS hardware.

TC-90™ BI-SPECTRAL CARD CAMERA

A compact, fixed-position thermal camera designed for continuous monitoring inside electrical panels and cabinets.

GridSafe™ Skid System

A semi-permanent deployment platform that supports embedded thermal monitoring across multiple electrical assets in the field.